Key Properties of Laid Scrim Film

One of the defining features of laid scrim film is its ability to provide enhanced durability without compromising flexibility. The scrim material reinforces the film, making it resistant to punctures, tears, and stretching. At the same time, the film layers can be tailored to offer various additional properties such as UV protection, waterproofing, or chemical resistance.

Other key properties include:

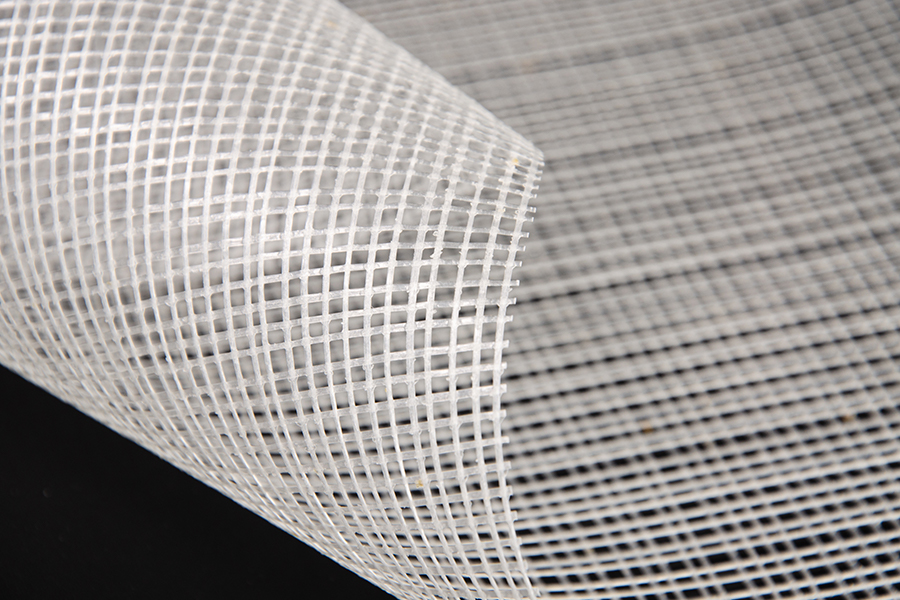

Tear Resistance: The scrim’s mesh-like structure adds tensile strength to the film, making it more resistant to tearing compared to traditional films.

Flexibility: Despite its strength, laid scrim film remains flexible and lightweight, making it easy to handle and apply in various industrial processes.

Customization: The film layers can be manufactured from different materials, such as polyethylene or polypropylene, allowing customization based on the application’s needs.

Temperature Resistance: Depending on the film material, laid scrim film can tolerate high or low temperatures, making it suitable for a wide range of environmental conditions.

Applications of Laid Scrim Film

Due to its versatile properties, laid scrim film is used in a broad array of industries:

Packaging: Laid scrim film is commonly employed in the packaging industry, where it helps create heavy-duty bags, sacks, and pallet covers. The scrim adds the required tensile strength to prevent tearing, especially when handling sharp or heavy objects.

Construction: In the construction industry, laid scrim film is used as a reinforcement material for roofing membranes, vapor barriers, and floor underlays. Its strength and resistance to environmental stress make it a critical component in ensuring the longevity of building materials.

Medical Applications: In the medical sector, laid scrim film is used in disposable medical products, such as gowns and drapes, where high strength and resistance to tearing are essential for safety.

Agriculture: Laid scrim film is also widely used in the agricultural industry, where it serves as greenhouse covers, silage covers, and other protective layers for crops. Its ability to withstand UV rays and varying temperatures makes it ideal for outdoor applications.

Environmental Considerations As industries increasingly prioritize sustainability, laid scrim film manufacturers are developing eco-friendly variants of the material. By incorporating recyclable or biodegradable films and scrim materials, the environmental impact can be reduced. Additionally, the strength of laid scrim film allows for lighter-weight packaging, reducing the overall material consumption in many applications.