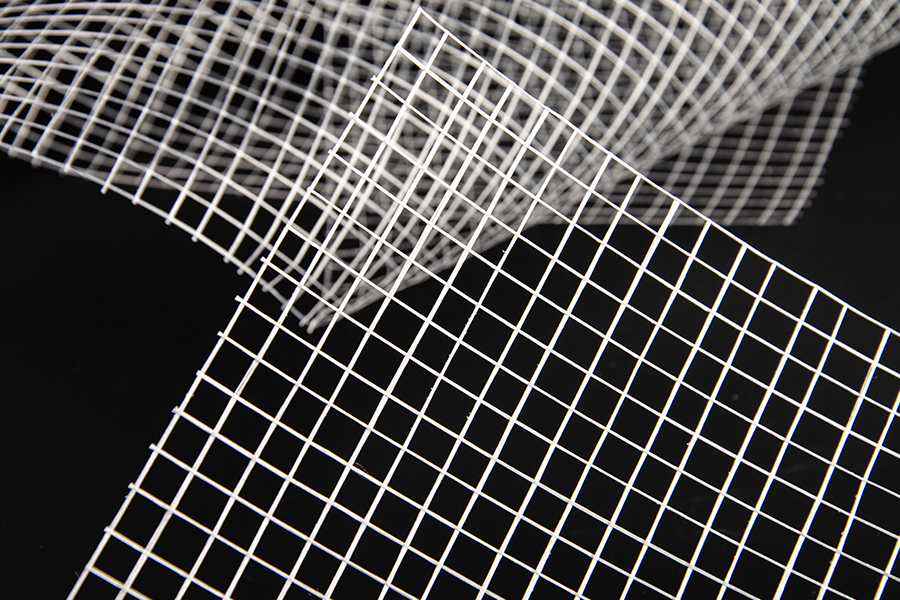

The Structure of Laid Scrim Film Laid scrim film is engineered through a process of laminating scrim between two layers of film. The scrim component typically consists of woven or non-woven polyester or fiberglass, while the film layers are made from materials like polyethylene or polypropylene. This multi-layered structure gives the film its unique properties: the scrim provides tensile strength and tear resistance, while the film layers offer additional protection from moisture, UV rays, or chemicals.

Advantages of Laid Scrim Film Laid scrim film offers a number of advantages that make it suitable for various demanding environments:

Superior Strength: Thanks to the reinforcement from the scrim layer, laid scrim film exhibits exceptional tensile strength. This makes it less prone to tearing or puncturing, even when used to package or protect sharp or heavy objects.

Lightweight Construction: Despite its strength, the film remains lightweight. This is crucial in industries like packaging and construction, where materials need to be easy to transport and install without sacrificing durability.

Customizable Layers: The film layers can be manufactured from various materials to meet specific requirements, such as UV resistance for outdoor applications or waterproofing for moisture-sensitive goods.

Cost-Effective: The enhanced strength of laid scrim film allows manufacturers to use less material while achieving the same level of protection, thereby reducing costs in the long run.

Applications Across Industries Laid scrim film is a go-to material for numerous industries:

Packaging Industry: In packaging, laid scrim film is often used to create heavy-duty sacks, shipping bags, and pallet covers. The film’s high tear resistance ensures that it can withstand the rigors of transportation, even when subjected to sharp or heavy contents.

Construction Sector: In the construction sector, laid scrim film is used as a reinforcement material in building membranes, vapor barriers, and floor underlays. Its strength and moisture-resistant properties make it a valuable component in ensuring the structural integrity of buildings.

Medical and Healthcare Products: Laid scrim film is utilized in the manufacture of disposable medical products, such as surgical drapes and protective clothing, where tear resistance and hygiene are critical.

Agricultural Uses: Farmers and agricultural producers benefit from laid scrim film in the form of greenhouse coverings, silage covers, and crop protection layers. Its ability to withstand harsh weather conditions makes it suitable for long-term outdoor use.

Sustainability in Laid Scrim Film As the world becomes more environmentally conscious, industries are seeking materials that are not only effective but also sustainable. Laid scrim film manufacturers have responded by developing eco-friendly alternatives that use recyclable or biodegradable materials. Furthermore, the strength of laid scrim film allows for thinner layers, which reduces overall material usage.