Laid scrim film has evolved into a highly versatile material that is relied upon in several critical sectors. The use of a scrim layer to reinforce film has opened up numerous applications where strength, flexibility, and durability are required.

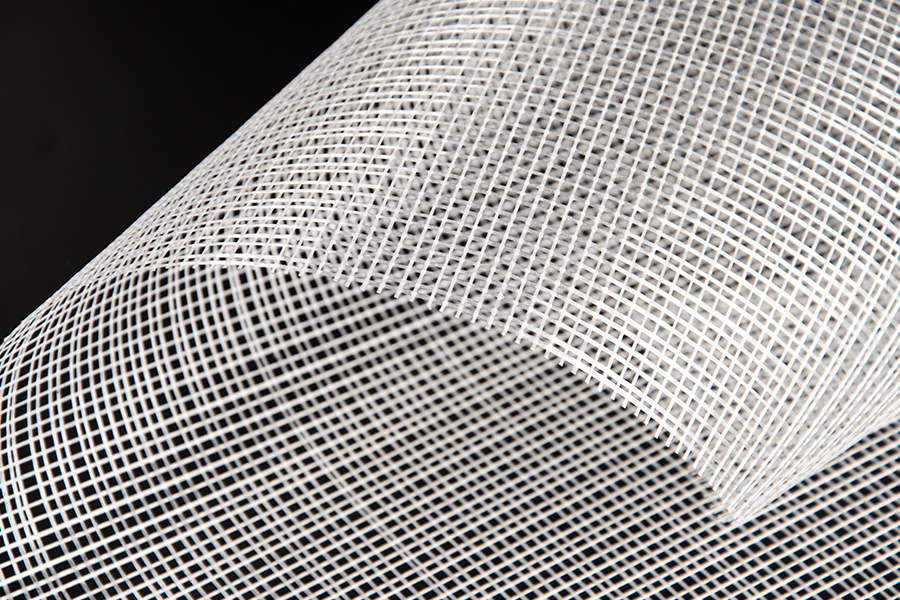

How Laid Scrim Film is Made Laid scrim film is produced by laminating a scrim material between two layers of protective film. The scrim is a lightweight mesh made of polyester, fiberglass, or other materials, while the outer films can be tailored for different applications. This method allows manufacturers to produce a composite material with superior tear resistance and adaptability.

Latest Innovations in Laid Scrim Film As industries demand more from their materials, the development of laid scrim film has kept pace with several innovative advancements:

Enhanced Durability: Recent innovations have focused on improving the tear strength of laid scrim film, enabling it to withstand even more rigorous conditions. This includes making scrim with higher tensile strength and using films with increased resistance to chemicals, UV light, and moisture.

Eco-Friendly Variants: With the growing emphasis on sustainability, manufacturers are developing laid scrim films that use biodegradable or recycled materials. This shift not only reduces environmental impact but also helps industries meet increasingly stringent regulatory standards.

Heat-Sealable Laid Scrim Film: For industries that rely on heat-sealing processes, such as packaging, new types of laid scrim films have been developed that can withstand the high temperatures required for sealing without losing their integrity.

Key Benefits of Laid Scrim Film The advancements in laid scrim film production have only strengthened its position as a key material in numerous industries. Some of the primary benefits include:

Exceptional Tear Resistance: The scrim layer serves as a reinforcing mesh that distributes stress across the film, making it less prone to tearing or puncturing.

Lightweight and Flexible: Despite its strength, laid scrim film remains lightweight and flexible, making it easy to handle in both manual and automated processes.

Versatile Applications: Whether used in packaging, construction, agriculture, or healthcare, laid scrim film is adaptable to a wide range of needs thanks to its customizable film layers.

Future Potential of Laid Scrim Film The future of laid scrim film looks promising, with ongoing innovations and increasing demand across several sectors. As industries prioritize sustainability, laid scrim film manufacturers will continue to develop eco-friendly materials without compromising strength or durability. Additionally, new applications in fields such as renewable energy or aerospace may emerge as industries recognize the value of lightweight, high-strength materials.