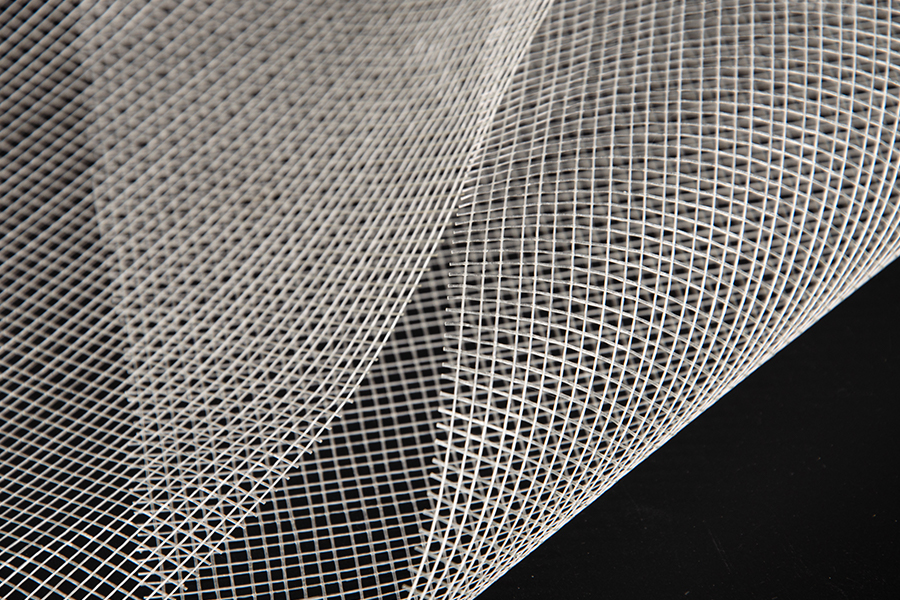

Fiberglass laid scrim has become a staple in various industries due to its remarkable properties and versatility. This lightweight, strong, and durable material is made from woven fiberglass fibers, providing an excellent reinforcement solution for multiple applications.

What is Fiberglass Laid Scrim?

Fiberglass laid scrim is constructed from fine strands of fiberglass woven together in a grid pattern. This design allows the material to deliver exceptional tensile strength and resistance to tearing, making it ideal for reinforcing various substrates. Often coated with a resin or adhesive, fiberglass scrim enhances bonding capabilities, which is crucial for ensuring stability in numerous applications.

Key Properties of Fiberglass Laid Scrim

High Strength-to-Weight Ratio: One of the standout features of fiberglass laid scrim is its ability to provide significant strength without adding substantial weight. This characteristic is vital in applications where structural integrity is paramount without compromising overall weight.

Chemical Resistance: Fiberglass is inherently resistant to many chemicals, making it suitable for environments that may expose materials to corrosive substances. This property ensures longevity and reliability in harsh conditions.

Lightweight Nature: The scrim’s lightweight composition facilitates easy handling and installation. This advantage is particularly beneficial in industries where weight considerations are critical, such as automotive and aerospace.

Flexibility and Ease of Use: Fiberglass laid scrim can be easily cut and shaped to meet specific requirements, making it adaptable to a wide range of projects.

Thermal Insulation: The material also provides good thermal insulation, making it suitable for applications where temperature control is necessary.

Common Applications of Fiberglass Laid Scrim

Construction: In the construction industry, fiberglass laid scrim is widely used in wall systems, roofs, and flooring. It reinforces these structures, providing additional strength and stability.

Automotive Manufacturing: In automotive applications, fiberglass scrim is employed to strengthen composite materials and components, contributing to overall vehicle efficiency and safety.

Marine Applications: The marine industry benefits from fiberglass laid scrim as it is used to reinforce boat hulls and other structures that face harsh weather conditions. Its resistance to water damage makes it an ideal choice.

Composite Manufacturing: In manufacturing, fiberglass scrim is a common reinforcement layer in composite materials, enhancing their mechanical properties and durability.

HVAC Systems: The scrim is also utilized in heating, ventilation, and air conditioning systems to reinforce insulation materials, improving energy efficiency and system performance.

Advantages of Fiberglass Laid Scrim

Cost-Effectiveness: Fiberglass laid scrim offers excellent performance at a relatively low cost. Its durability and strength reduce the need for frequent replacements, leading to significant long-term savings.

Enhanced Performance: Incorporating fiberglass laid scrim into products boosts their overall performance, offering added strength and resilience that can withstand demanding conditions.

Sustainability: Fiberglass is a recyclable material, making it an eco-friendly option for various applications. By utilizing fiberglass scrim, industries can support sustainable practices and reduce waste.

Easy Installation: The lightweight nature of fiberglass laid scrim simplifies transportation and installation processes, minimizing labor costs and project timelines.