Polyester Scrim is a key material used to strengthen composites and structural applications. With its unique structure and excellent performance, it occupies an important position in modern industry. This article will explore the structural characteristics, application scenarios and impact of polyester fiber mesh on modern industry.

1. Structure and performance of polyester fiber mesh

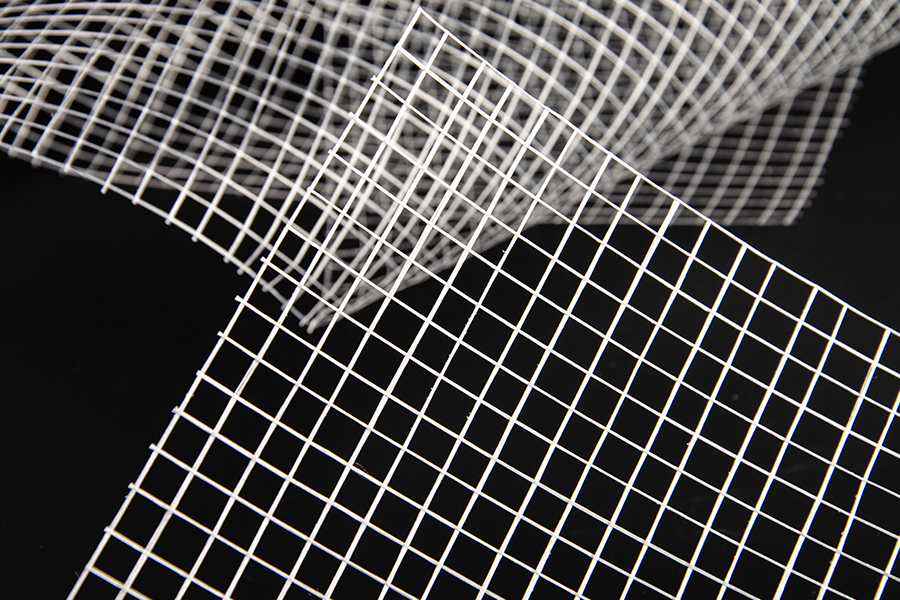

Polyester fiber mesh cloth is woven from strong polyester fiber. Its open mesh design makes the material both high strength and excellent permeability. This special weave allows the mesh to provide support in a variety of applications without adding extra weight. Its durability and dimensional stability make it an ideal material for the industrial and construction industries.

The main properties of polyester fiber mesh include:

High tensile strength: In composite materials, polyester fiber mesh can significantly improve the tensile properties of the material, thereby enhancing the overall structural strength of the product.

Chemical Resistance: It is resistant to many common chemicals and solvents, maintaining performance in harsh chemical environments.

Dimensional stability: Under high temperature or severe cold conditions, the size of the mesh remains stable and will not shrink or expand.

LIGHTWEIGHT AND EASY TO USE: This material is lightweight, easy to transport and process, and can be cut and installed easily.

2. Industrial application of polyester fiber mesh

Polyester fiber mesh has a wide range of applications, covering many industries from construction to automobile manufacturing:

Construction and Infrastructure: In the construction industry, polyester mesh is commonly used for wall reinforcement, roof waterproofing and road reinforcement. Not only does it enhance the structural strength of building materials, it also helps extend the life of the building.

Automobile manufacturing: In automobile manufacturing, polyester fiber mesh is used in the manufacture of composite materials such as body panels and interior parts. Its addition reduces vehicle weight, thereby improving fuel efficiency.

Packaging and Industrial Materials: In the packaging industry, polyester mesh is often used to reinforce flexible packaging materials, making them more tear-resistant. In industrial production, mesh cloth is also used as a reinforcing layer for conveyor belts, filter materials and reinforced membranes.

3. Environmental contribution of polyester fiber mesh

With the increasing awareness of environmental protection, the production methods of polyester fiber mesh are also constantly improving. Many manufacturers use recycled polyester materials to produce mesh to reduce their environmental impact. In addition, due to its durability, polyester mesh has a long service life, reducing the frequency of replacement and thus reducing waste generation.