Understanding Glass Fiber Enhancement Scrim

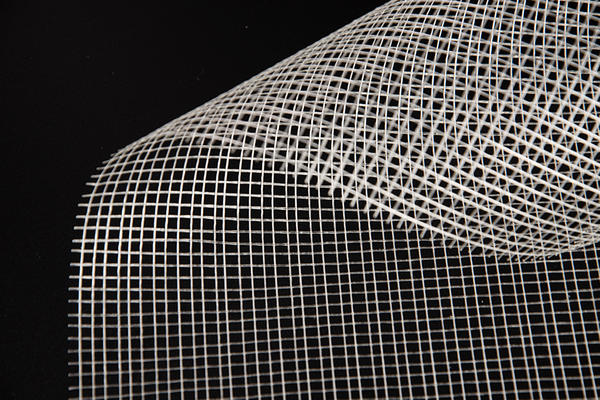

Glass fiber scrim is a fabric made from finely woven glass fibers designed to enhance the performance of composite materials. This scrim serves as a reinforcement in various resins and polymers, improving their overall strength, durability, and performance under stress. It is typically woven into a mesh-like pattern, allowing for an optimal balance between structural support and flexibility.

The role of the scrim is crucial: it provides additional tensile strength to composite materials, especially when combined with high-strength resin systems. The glass fibers themselves are inherently resistant to heat, moisture, and chemical corrosion, making the scrim highly durable and capable of withstanding harsh environments.

Key Benefits of Glass Fiber Scrim

Enhanced Mechanical Properties: Glass fiber scrim increases the strength and stiffness of the composite material without adding significant weight. This makes it ideal for industries where material weight is a crucial factor, such as the automotive and aerospace industries. The glass fibers help to distribute mechanical loads evenly across the material, improving its ability to resist cracking, stretching, and impact.

Superior Flexibility: Unlike solid glass fiber mats, the open weave structure of a glass fiber enhancement scrim allows it to maintain a certain degree of flexibility. This is important for applications where the composite needs to be molded into complex shapes or adjusted to fit specific design requirements.

Resistance to Environmental Factors: Glass fiber scrim is resistant to a wide range of environmental stressors, including moisture, chemicals, and UV radiation. This makes it particularly useful in outdoor applications or environments where exposure to harsh weather conditions is common.

Easy Integration with Resin Systems: One of the major advantages of using glass fiber scrim is its ability to bond well with various resin systems, including epoxy, polyester, and vinyl ester. This compatibility ensures that the scrim can be used across a wide range of industries and applications, from marine and automotive to construction and wind energy.

Applications of Glass Fiber Enhancement Scrim

The versatility of glass fiber scrim has made it a go-to solution in many manufacturing sectors. Here’s how it’s used in different industries:

Construction: In construction, glass fiber scrim is employed to reinforce materials such as concrete, plaster, and tiles. It increases the material's resistance to cracking and enhances its ability to withstand external stresses. Additionally, glass fiber scrim helps improve the longevity of insulation boards and roofing materials by preventing premature wear and tear.

Automotive: The automotive industry increasingly uses lightweight composite materials to improve fuel efficiency and vehicle performance. Glass fiber scrim is incorporated into composite parts such as body panels, bumpers, and door panels to improve their impact resistance and overall strength without adding significant weight. This contributes to the reduction of the vehicle's overall weight, which is crucial for meeting fuel economy standards.

Marine: In the marine industry, composite materials reinforced with glass fiber scrim are used in the construction of boats and other watercraft. The scrim provides enhanced durability, especially in environments where the materials are frequently exposed to water and harsh weather conditions. It also improves the structural integrity of hulls and decks.

Aerospace: Aerospace engineers rely on glass fiber scrim for its high-strength-to-weight ratio. Components such as fuselage parts, wings, and interiors are often made with composite materials that incorporate glass fiber scrim for added durability and safety without compromising weight, which is critical in flight operations.