Glass fiber enhancement scrim is a specialized fabric made from woven or non-woven glass fibers. This material is designed to be used in combination with resin or other bonding agents to enhance the mechanical properties of a composite. Scrims are typically lightweight but feature excellent tensile strength, making them ideal for reinforcing materials. The glass fibers themselves are resistant to high temperatures, moisture, and corrosion, and the scrim structure improves the material’s ability to hold its form and resist deformation under stress.

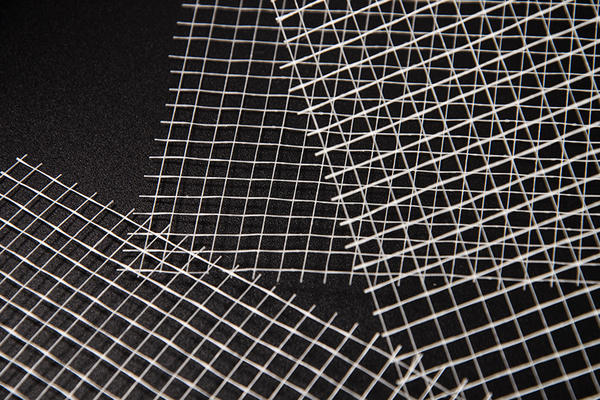

The manufacturing process for glass fiber scrim involves weaving glass filaments in a specific pattern to create a mesh-like fabric. The filaments are interwoven, allowing the scrim to have an open weave that makes it easy for resins to penetrate and bond effectively. This results in enhanced structural integrity once the scrim is combined with a resin system to create the final composite material.

Applications of Glass Fiber Enhancement Scrim

Glass fiber enhancement scrim is widely used in various sectors due to its ability to improve the performance of different materials. Here are some of the major applications:

Construction: In construction, glass fiber scrim is used to reinforce cement, concrete, and plaster. It helps to enhance the strength of the material, reduce cracking, and increase its resistance to water penetration. It's also commonly used in the manufacturing of insulation boards, where its strength helps the material resist the stresses of heavy-duty environments.

Automotive: The automotive industry relies heavily on lightweight yet durable materials to enhance fuel efficiency and vehicle performance. Glass fiber scrims are commonly used in composites for car body parts, offering the perfect balance of strength and lightness. They can also be found in automotive upholstery, where they improve the material's tear resistance and overall durability.

Aerospace: In aerospace applications, weight reduction without compromising on safety or performance is a key consideration. Glass fiber scrim is used in aircraft parts, where its high strength-to-weight ratio ensures that materials can withstand the extreme conditions of flight while maintaining structural integrity.

Wind Energy: The renewable energy sector, particularly wind turbine blade production, also benefits from glass fiber scrim. The scrim enhances the strength of composite materials, enabling wind turbine blades to handle high-stress environments while remaining lightweight and durable.

Advantages of Glass Fiber Enhancement Scrim

Increased Durability: One of the primary reasons industries turn to glass fiber scrim is its ability to enhance the longevity of materials. The combination of glass fiber’s resistance to wear, tear, and corrosion ensures that products reinforced with scrim can withstand extreme environmental conditions.

Lightweight Yet Strong: Glass fiber scrim offers a unique combination of strength and lightness. This makes it particularly useful in industries like automotive and aerospace, where weight reduction is as important as structural integrity.

Improved Flexibility and Adaptability: The mesh-like structure of glass fiber enhancement scrim allows for flexibility in terms of integration with various resin systems. It can be used in a wide range of applications, including both rigid and flexible composite materials.

Cost-Effectiveness: While glass fiber scrim may initially seem like a premium product, it provides a cost-effective solution in the long run. Its ability to enhance the durability and performance of materials reduces maintenance and repair costs over time.