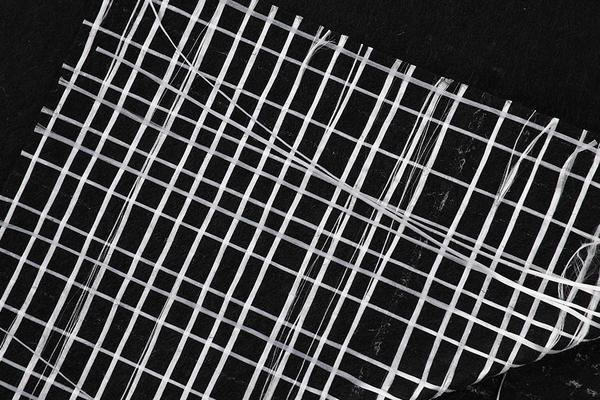

Non-woven geotextile fabric is a versatile and essential material in modern civil engineering and construction. Unlike woven geotextiles, which are made by interlacing yarns, non-woven geotextiles are produced by bonding fibers together through methods such as needle punching, heat bonding, or chemical bonding. This results in a fabric that offers distinct advantages in various applications.

Non-woven geotextile fabric is created from synthetic fibers such as polypropylene or polyester. These fibers are randomly oriented and bonded together, resulting in a fabric that is highly permeable and durable. The primary functions of non-woven geotextiles include filtration, separation, drainage, and reinforcement, making them invaluable in construction projects.

Key Benefits

Excellent Filtration Properties: Non-woven geotextiles are designed to allow water to flow through while filtering out soil particles. This characteristic is crucial in preventing soil erosion and maintaining soil stability in areas prone to water flow.

Enhanced Drainage: The high permeability of non-woven geotextiles facilitates effective water drainage. This property is particularly beneficial in areas with poor natural drainage, such as roadways, retaining walls, and embankments, where water accumulation can lead to structural damage.

Soil Separation and Reinforcement: By preventing the mixing of different soil types, non-woven geotextiles maintain the integrity of soil layers. This separation is vital in construction applications like road building and earthworks, where different soil types need to be kept distinct to ensure stability and performance.

Durability and Longevity: Non-woven geotextiles are known for their strength and durability. They can withstand harsh environmental conditions, including exposure to UV rays, extreme temperatures, and chemical attacks. This longevity ensures that the fabric will perform effectively over the long term.

Applications

Road Construction: In road construction, non-woven geotextiles are used to improve the performance of the road base and sub-base. They provide separation between the aggregate and the subgrade soil, reducing the risk of mixing and ensuring a stable foundation.

Erosion Control: Non-woven geotextiles are employed in erosion control measures, such as reinforcing slopes and riverbanks. They help to stabilize soil and prevent erosion caused by water flow, thus protecting valuable land and infrastructure.

Landscaping and Drainage: In landscaping applications, non-woven geotextiles are used to separate soil layers and prevent the mixing of different materials. They are also used in drainage systems to enhance water flow and prevent clogging.

Retaining Walls: Non-woven geotextiles are used behind retaining walls to provide drainage and prevent water pressure buildup. This reduces the risk of wall failure and extends the lifespan of the structure.